Showing 1–24 of 78 results

Sort by

OK Aristorod 69 (ER110S-G) Гагнуурын утас / ESAB

Esab, Даацын гангийн утас / Tensile Steel / High Tensile Steel, Гагнуурын электрод болон утаснууд / Welding Consumables

OK Aristorod 69 (ER110S-G)

Стандарт:

SFA/AWS A5.28 ER110S-G

A low-alloyed, chromium-nickel-molybdenum (0,3% Cr, 1,4% Ni, 0,25% Mo), solid wire for GMAW of high tensile strength steels requiring tough weld metal for critical applications. Also suitable when high impact strength at lower temperatures is required.

Stoody 850 Хуяглалтын гагнуурын утас / ESAB

Esab, Хуяглалтын зориулалттай утас / Hard Facing, Гагнуурын электрод болон утаснууд / Welding Consumables

- Self Shielded (-O), Tubular Hardfacing Wire

- Air Hardening, Crack Prone High Carbon, Martensitic Steel Deposit

- Resistant to Severe Abrasion and Low Impact Loading

- 1.2mm size can be used for vertical surfacing by depositing overlapping horizontal stringer passes

Stoody 965 Хуяглалтын гагнуурын утас / ESAB

Esab, Хуяглалтын зориулалттай утас / Hard Facing, Гагнуурын электрод болон утаснууд / Welding Consumables

- Gas (-G) and Self Shielded (-O), Tubular Hardfacing WiresAir Hardening, Crack Free, Martensitic Steel Deposit

- Resistant to Hard Particle Abrasion and Moderate Impact Loading

- 1.2mm and 1.6mm sizes can be used for vertical surfacing by depositing overlapping horizontal stringer passes

- 1.2mm and 1.6mm wires are B5 type wires which require a shielding gas

- 2.4mm size is a B7 type open arc wire which requires no shielding gas

SC-350H Хуяглалтын гагнуурын утас / Hyundai Welding

Hyundai Welding, Хуяглалтын зориулалттай утас / Hard Facing, Гагнуурын электрод болон утаснууд / Welding Consumables

Applications:

For intermetallic abrasion, hardfacing of roller, gear, etc.

Cradling welding between worn metals

SC-350H is a flux cored wire designed for hardfacing application with

100% CO2 shielding gas. It is highly recommendable to use on wear

plate and weld metal’s hardness should be over Hv 350

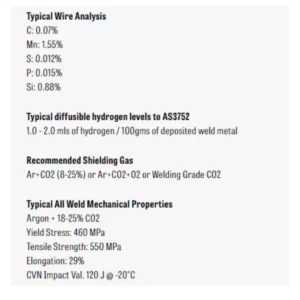

Autocraft LW1-6 ГАГНУУРЫН УТАС / CIGWELD

SPW, Нүүрстөрөгчит төмрийн утас / Mild Steel, Гагнуурын электрод болон утаснууд / Welding Consumables

Standard:

ISO AS/NZS 14341: B G 49A 3U C1/M21/M24 S6

AWS/ASME-SFA A5.18: ER70S-6.

Autocraft LW1-6 is a high quality copper coated welding wire suitable for the all positional Gas Metal Arc Welding (GMAW) of mild and low alloy steels, used in general fabrication and structural work

Features & Benefits;

- A higher manganese/silicon steel wire for GMA Welding

- Use with CO2 and Argon based shielding gases

- Wide Range of minispool, handispool and Autopak packaging options

- Suitable for positional Gas Metal Arc Welding (GMAW) of mild and low alloy steels, used in general fabrication and structural work

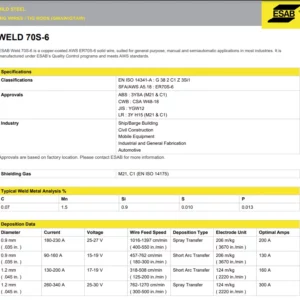

SC-81MC ГАГНУУРЫН УТАС / Hyundai Welding

Hyundai Welding, Хагас автомат гагнуурын утас / MIG Wires, Даацын гангийн утас / Tensile Steel / High Tensile Steel, Гагнуурын электрод болон утаснууд / Welding Consumables

Стандарт: AWS A5.29 E81T1-Ni1M-J H4

SC-81M is an all position flux cored wire designed for Ar+20~25%

CO2 shielding. You can get smooth arc, and low spatter, good

weldability. The weld metal impact values at –60℃(-76℉) is

excellent and has good bead appearance, slag covering is uniform

and easy to remove.

ESAB ШИРЭМНИЙ ЭЛЕКТРОД / OK 92.18

OK 92.18

SMAW

Type Basic-special, high graphite

A nickel-cored electrode for welding normal grades of cast iron. The weld metal is soft and easily machinable. Deposition is performed on cold or slightly preheated material. The electrode is suitable for the joining/repair of grey and malleable cast irons and the joining of these cast irons to steel, monel and copper.

Thin sections can be welded cold but it is recommended that preheat be used when welding thicker sections. When welding select the smallest diameter electrode practical and operate at low currents to keep dilution to a minimum. Stringer beads should be deposited using a stepped short run technique to avoid overheating of the workpiece.

During welding the joint can be lightly peened and on completion the workpiece should be allowed to cool slowly.

Welding current:

AC, DC+/- Min OCV 50 V

CIGWELD ШИРЭМНИЙ ЭЛЕКТРОД

308,000₮

Castcraft 100 is a basic, graphite coated electrode manufactured by CIGWELD for the repair and maintenance of a wide range of cast iron components.(Core wire is made up of 98%Ni)

Packaging Data

- 611732N – 2.5mm – 2kg Pack

- 611733N – 3.2mm – 2.2kg Pack

- Maintenance Welding of Cast Irons

- Lime Fluorspar / Graphite Coating

- Soft, Ductile Nickel Deposit

- Easy starting and Stable Running on Portable 240V Welding Machines

- Smoother Weld Deposit Surface Finish

Cobalarc 750 / CIGWELD

Cobalarc 750 is a smooth running, rutile type electrode specifically designed for AC hard surfacing applications.

Packaging Data

611473 – 3.2 mm – 5kg Pack

611474 – 4.0 mm – 5kg Pack

Features & Benefits

- Resistant to Hard Particle Abrasion

- Air hardening, crack-free, martensitic steel deposit – 750 HV30

- Easy arc start and stable running on portable AC welding sets (>45 O.C.V)

Cobalarc 650 / CIGWELD

Cobalarc 650 is a basic electrode for the hard surfacing of steel components subjected to wet or dry hard particle abrasion and low to moderate impact loading.

5kg Variations

- 611463 – 3.2 mm

- 611464 – 4.0 mm

- Basic Type Manual Arc Welding Electrode

- Resistant to hard particle abrasion and moderate impact loading

- Air hardening, crack-free martensitic steel deposit- 650 HV 30\

Cobalarc Borochrome / CIGWELD

Cobalarc BOROCHROME is a popular high alloy extruded hard surfacing electrode manufactured by CIGWELD

5kg Variations

613964 – 4.0mm

613965 – 5.0mm

Highly Alloyed Manual Arc Electrode

Martensitic Chromium Carbide Iron Deposit

Ideal for Fine Particle (Wet or Dry)

Abrasion and Low Impact Loading

Primary Chromium Iron Carbides in a Hard, Martensitic Matrix

Cobalarc Austex / CIGWELD

Cobalarc AUSTEX is a metal enriched, Rutile type extruded electrode

Packaging Data

613973 – 3.2mm – 5kg Pack

613974 – 4.0mm – 5kg Pack

613975 – 5.0mm – 5kg Pack

Features & Benefits

- Metal Enriched, Rutile Type Electrode

- For joining dissimilar steels or as a buffer later prior to hard surfacing

- Tough, machinable austenitic stainless steel deposit

S-700B.B ЭЛЕКТРОД / Hyundai Welding

Hyundai Welding, Гагнуурын электрод / Stick Electrodes, Хуяглалтын зориулалттай электрод / Hard Facing

Онцлог:

- Араа, краны дугуй, рольк /ган дугуй/ гэх мэт элэгдэлд тэсвэртэй ганг хуяглах, шавах зэрэгт ( AC or DC± )

- Гагнагдах материалыг 150⁰С-с дээш урьдчилан халааж гагнавал илүү үр дүнтэй

- Боломжтой бол 600⁰С-д халааж аажимаар зууханд хөргөж дулааны боловсруулалт хийвэл илүү цууралтанд тэсвэртэй, чанартай болно

- Мартенсит бүтэцтэй ганд тохиромжтой

- Гагнасны дараа Машинаар гадаргуун боловсруулалт хийх боломжгүй

- Хөрс, шороо зэрэгт тэсвэртэй эд ангид ашиглана

CIGWELD Аргоны электрод / Comweld AL4043

Comweld AL4043 is premium quality Aluminium – nominal % Silicon Alloy rod used extensively for the repair welding of selected* Aluminium alloy castings

- 321610 – 1.6mm – 2.5kg

- 321611 – 2.4mm – 2.5kg

- 321612 – 3.2mm – 2.5kg

- Aluminium – 5% Silicon Alloy Rod

- Suitable for Gas Welding and Gas Tungsten Arc (GTAW / TIG) Welding Applications

- Embossed with AS / AWS Class 4043′

- For the repair welding (fractures and blow holes etc) of selected aluminium alloy castings